Feeding Cable Through Conduit

Slip any additional wire s several inches into the loop fold over and wrap around the first wire.

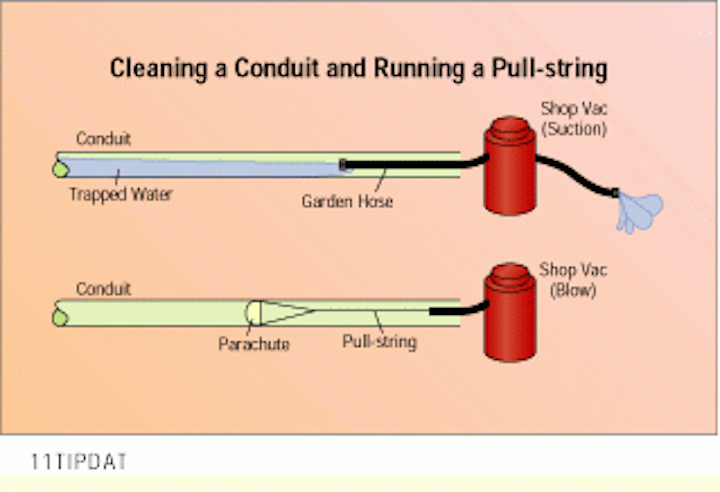

Feeding cable through conduit. Wire pulling compound is a non conductive lubricant in either a gel or a slimy soapy form that makes both the conduit and wires slick by coating the wiring allowing. Place your wire box so that it is free to leave the box and freely enter the conduit. Wire is pulled through chases conduit or knockouts to get from the electrical supply to the final destination. Instead connect only one wire directly to the string create one or more loops in this wire 6 8 or more inches down the wire from the connection point.

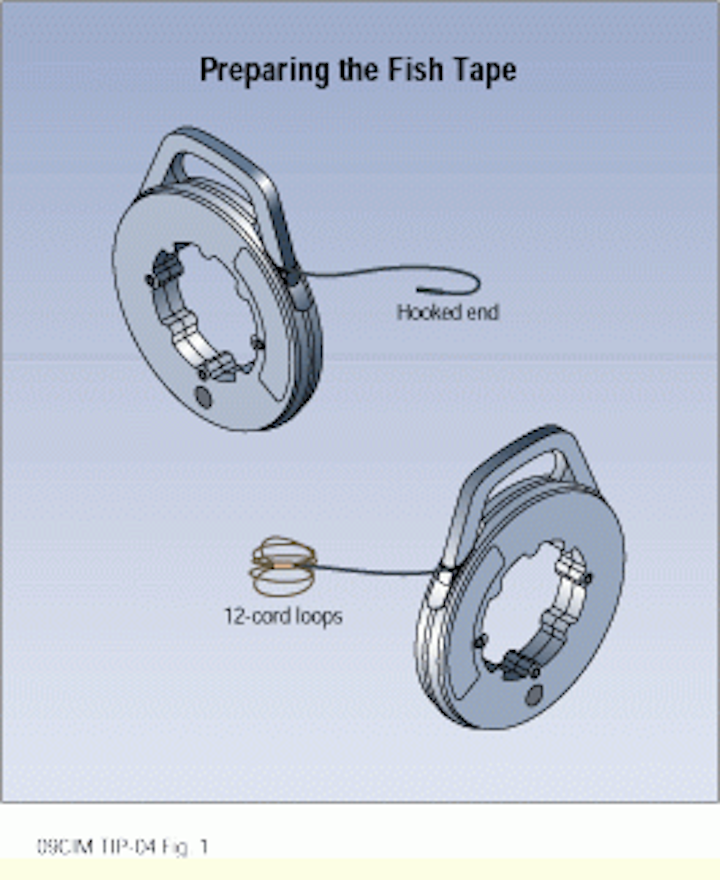

Use tape to fix the end like you pull wire. This involves pulling at one end of the run and feeding at the other. Make a loop in the feed cable the same size as the one in the pull wire. A fish tape is a thin sturdy wire inside of a plastic housing and acts like a snake to move through conduit.

Position your box of wire so that it will freely leave the box and will enter freely into the conduit. While using a wire fill table for electrical conduit it is best to size the conduit up to the next incremental size to be sure the conduit is not overfilled and it will make pulling in. Step 3 pull the wire through the conduit. Secure the end with tape as you did with the pull wire.

Pulling wires can be difficult enough through straight runs of conduit but throwing a few bends and turns in the run increases friction making pulling much more difficult that s when you use a lubricant. Electrical employees run or pull wire throughout a worksite. This path is usually under the floor or in the ceiling. Pass the end of the wire or cable through the ring that you make in the wire.

Feed the end of the wire or cable through the loop you made in the pull wire. Go to the other end of the conduit. A ring of the same size as a drawing wire is made in the feed cable. The housing can usually be cranked to feed or reel in the tape.

Lubricating the wires.