Fiber Optic Cable Inspection Checklist

Coordination with facilities and electrical personnel complete.

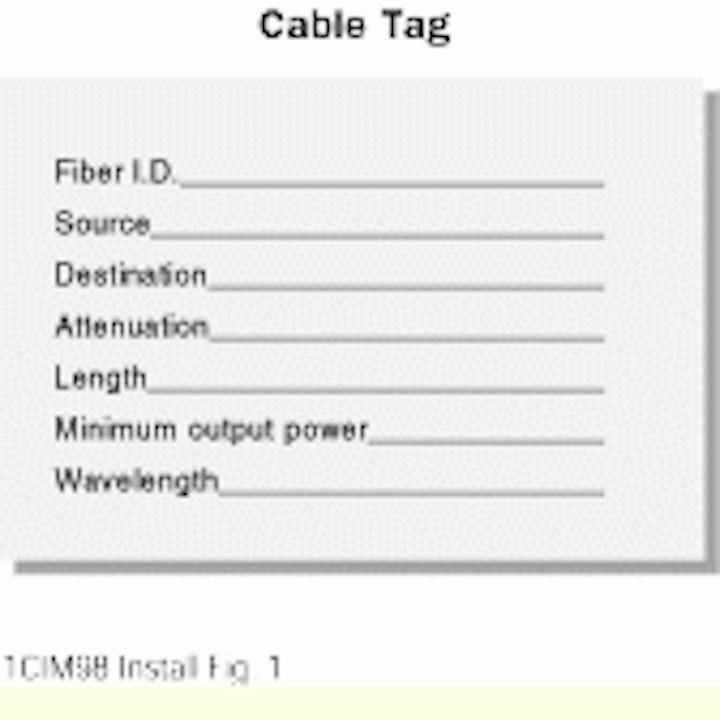

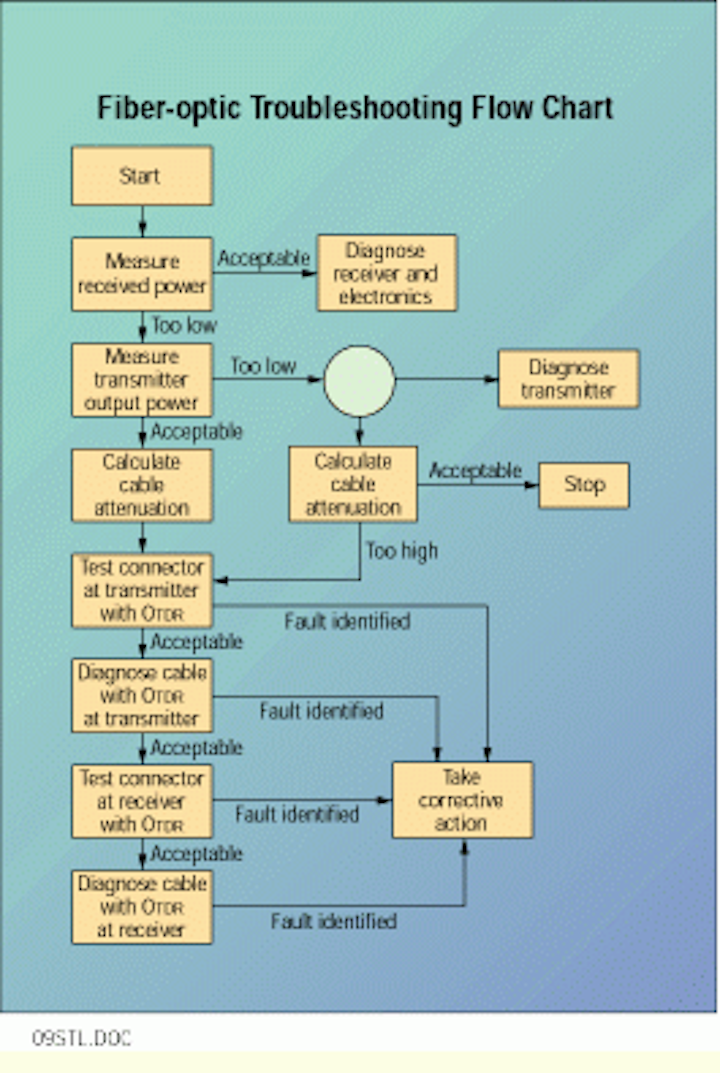

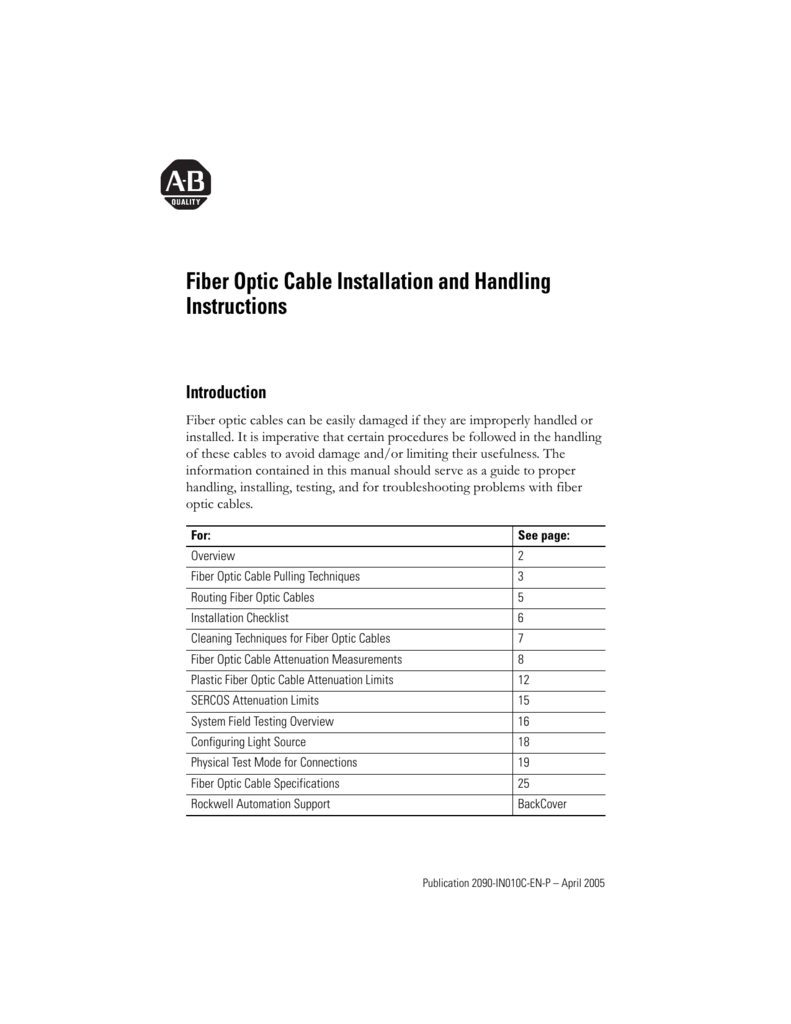

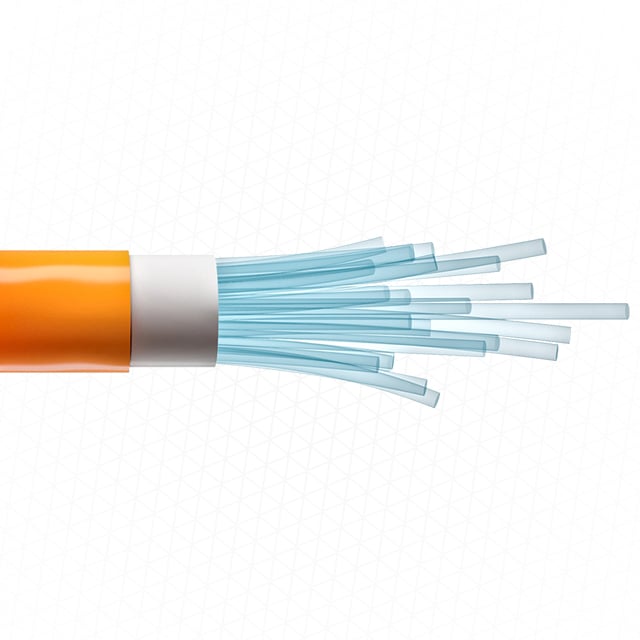

Fiber optic cable inspection checklist. This document is intended for use by service personnel field service technicians and hardware installers. 0b ppd inspection checklist and signature sheet. For every fiber optic cable plant you need to test for continuity and polarity end to end insertion loss and then troubleshoot any. The cable is comprised of optical fibers that are concentric cylinders made of dielectric materials i e nonmetallic materials that do not conduct.

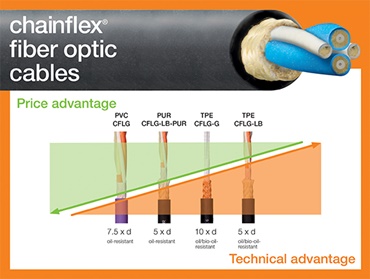

It is reliable a proven technology and cost effective making fiber optic cable the best media for its systems. It is a fact that fiber end face contamination is a major cause of network outages and downtime. Class 1 class 2 class 3 remote control signaling and power limited circuits checklist 12 2. Field test procedure for optical fiber link measurements keywords otdr olts sls opm attenuation issued april 2014 abstract after fiber optic cables are installed spliced and terminated they must be tested.

C o m. Fiber optic cable provides ample bandwidth for all its applications including video. Cable plant components and vendors chosen. Signaling and fire alarm circuits and optical fiber cables checklist 12 1.

3 in a fiber optic channel link the fiber cable and fiber components used belong to the same mode. 10 fiber cable has been installed in separate raceways and not mixed with copper cable. Uf fiber optic entrance cable. I n f i n i q u e.

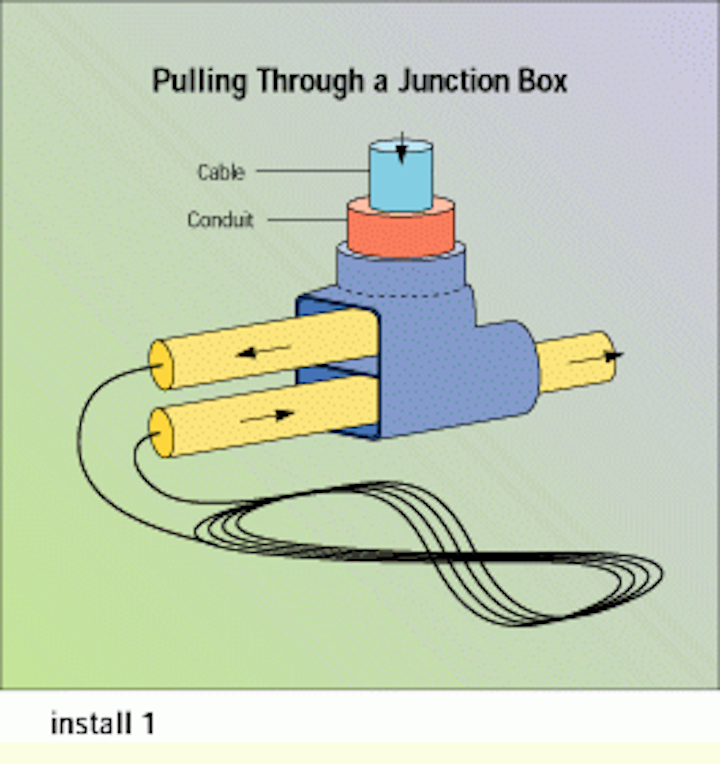

The foa reference guide to fiber optics. 24 48 hrs. Structured cabling system installation checklist copper and fiber systems w w w. Installation checklist planning for the installation is a critical phase of any project as it involves coordinating activites of many people and companies.

Afl fiber inspection products enable network technicians and other personnel to safely inspect fiber endfaces for contamination and verify the effectiveness of fiber cleaning procedures. Cable installation including pair count and fiber type is consistent with design requirements and carried out in a professional manner with appropriate slack 10 ft available in the entrance facility. The procedures in this document describe basic inspection techniques and processes of cleaning for fiber optic cables bulkheads and adapters used in fiber optic connections. There is an opportunity to remove subjectivity in the inspection of fiber optic end face and replace it with an objective process.

This pdf contains 77 electrical inspection checklists taken from the 2014 electrical inspection manual with.