Flame Straightening Sheet Metal

If expansion is restricted stresses build up.

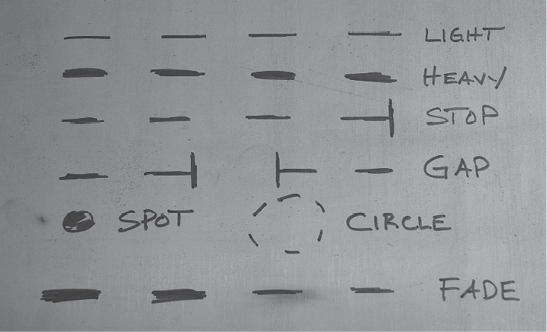

Flame straightening sheet metal. The flame straightening uses this new deformation to correct the original deformation. Flame straightening is an efficient well established method of correcting the weld distortion without impairing the material. Suitable materials include steel nickel copper brass and aluminium. Flame straightening is the straightening of deformed steel using the method of local flame heating.

The torch can now be moved along the length of the area to be straightened. The heat shrink begins at an edge or in a single spot. When straightening stainless steel heat it only until a deep brown color is seen on the surface. Body files are usually used after another age old process has been used to straighten or shrink sheetmetal.

Upon cooling the metal contracts more than it could expand when heated and any resulting distortions can therefore be straightened out. Removing deformations with an oxy acetylene flame this process is based on the physical principle that metals expand when heated and contract when cooled. In practice an oxy acetylene flame is used to rapidly heat a well defined section of the workpiece.