Flat Surface Between Two Bends In Sheet Metal

With this free online tool we quickly get the sheet metal bend deduction and therefore the sheet metal blank initial flat length from the finished part measurements.

Flat surface between two bends in sheet metal. The force must exceed the material s yield strength to achieve a plastic deformation. You can use this sheet metal flat pattern calculator to calculate this increase in length. Kink a light bend typically between 5 and 15 which is used to stiffen a flat piece of metal. Bend deduction is equal to the difference between the total sheet metal length after bending and flat length.

If the metal is still getting scratched up you can either put on a few layers of masking tape or use wood blocks like 2 4 s or something to sandwich the part for bending as you tap away on it with a mallet the wood will be soft enough to not damage the surface as long as there aren t any metal shavings hard things on it. The press brake contains an upper tool called the punch and lower tool called the die between which the sheet metal is placed. These methods will give sheet metal the rigidity you need to use it in a structural or semi structural application. Since each metal fabricator has its own tooling bend factors and equipment to develop the flat blank it is better to fully dimension to formed views for that manufacturer.

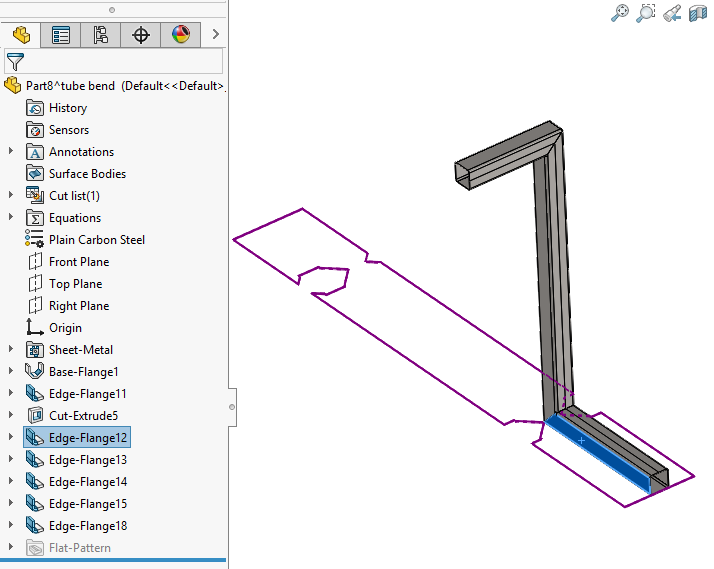

Your manufacturer may not be able to match dimensions when creating the actual sheet metal part due to tooling and equipment limitations. The problem i have is to make a smooth transition between a flat and a bent surface. Also known as press braking flanging die bending folding and edging this method is used to deform a material to an angular shape. The sheet is placed between the two and held in place by the backstop.

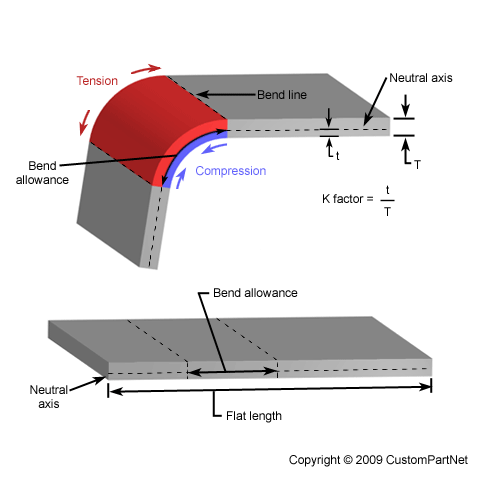

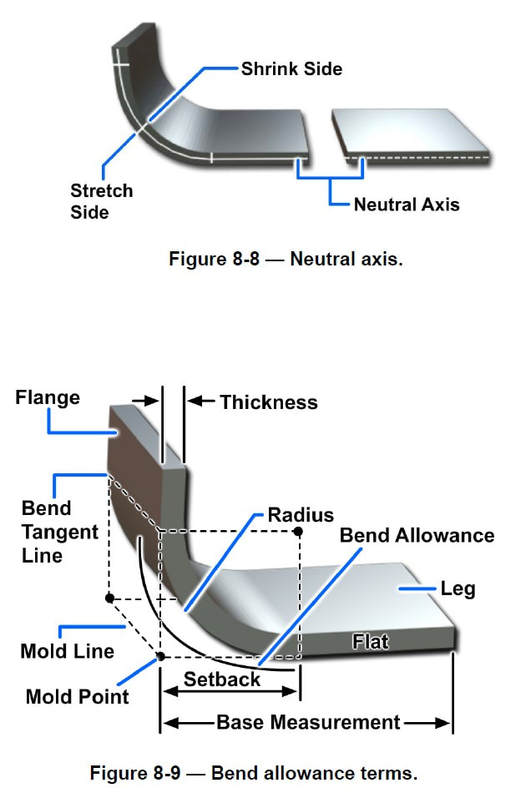

Whereas the outer surface is stretched. Folding over the edge of a piece of sheet metal will give the metal instant structural integrity. Therefore after bending total sheetmetal part length a b is greater than sheet metal flat length. The bend angle is determined by the depth that the punch forces the sheet into the die.

This is done through the application of force on a workpiece. Jog also known as an offset bend this is when two bends of the same angle but opposite direction are used to create a z shaped profile. Hems can be flattened left open or in a variety of tear drop shapes. You only have to insert interior angle flange lengths k factor inside radius and material thickness.

As a result overall sheet length increases. Sheet metal edge bending. I don t have much experience using sheet metal and need some help to check if what i m trying to achieve is possible using sheet metal or if i should use some other method. How large of a bend you put in the metal depends on the application and fitment of the piece.

When sheet metal is bend the inside bending surface is compressed.