Flex Circuit Design Rules

Flexible circuits design guide.

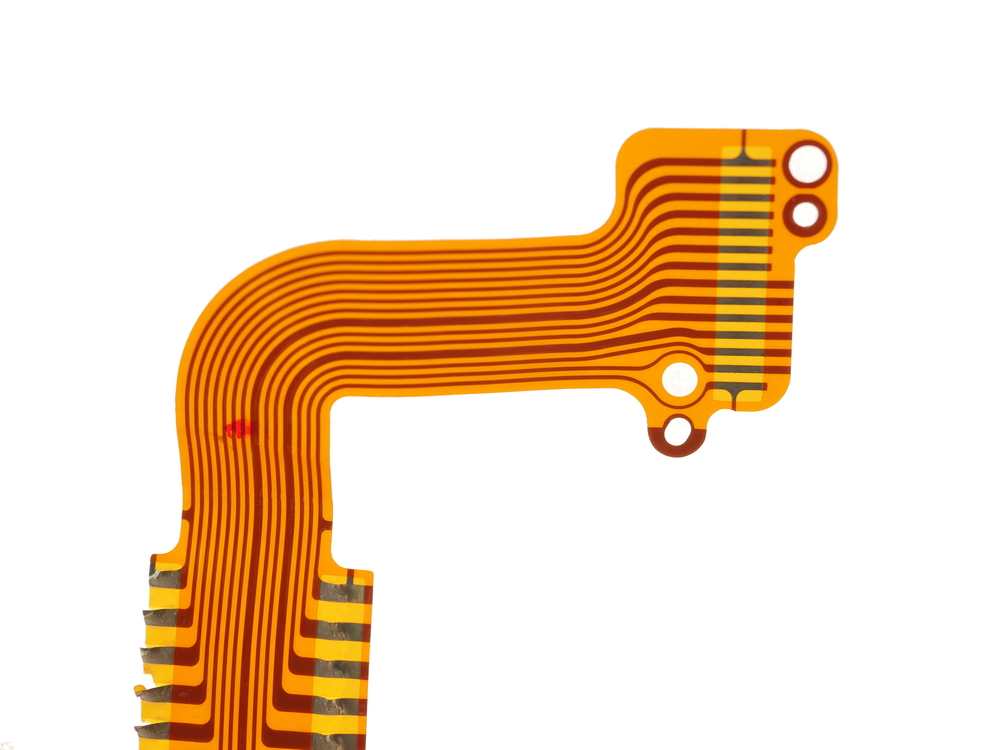

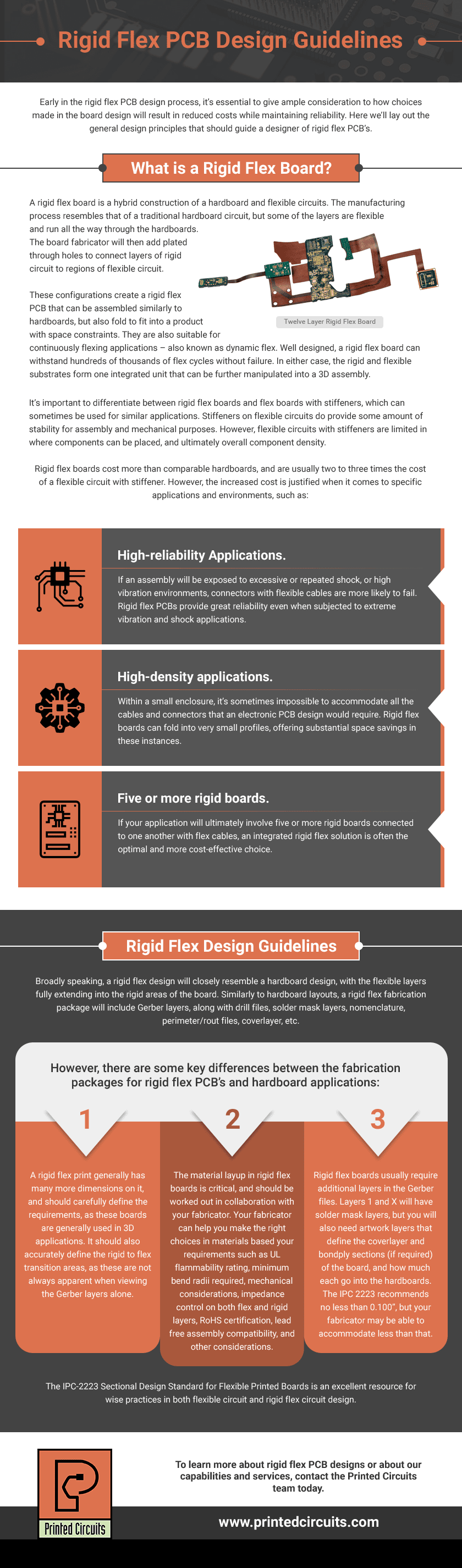

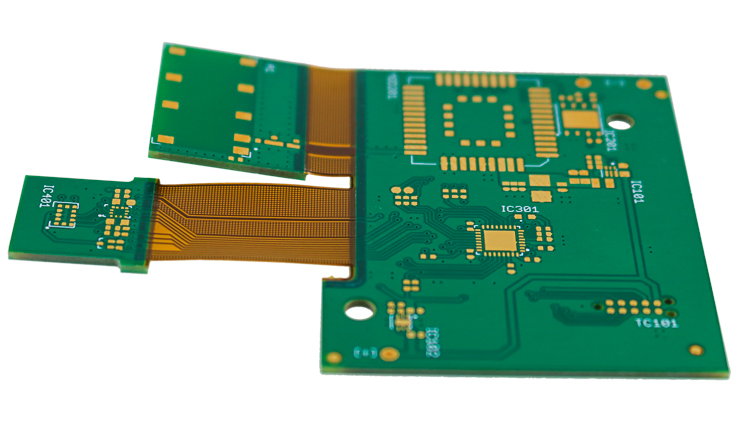

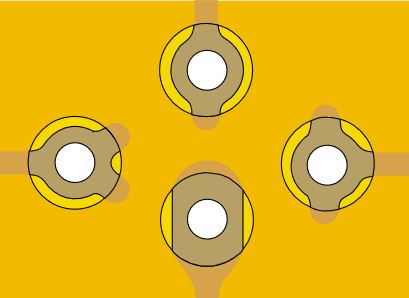

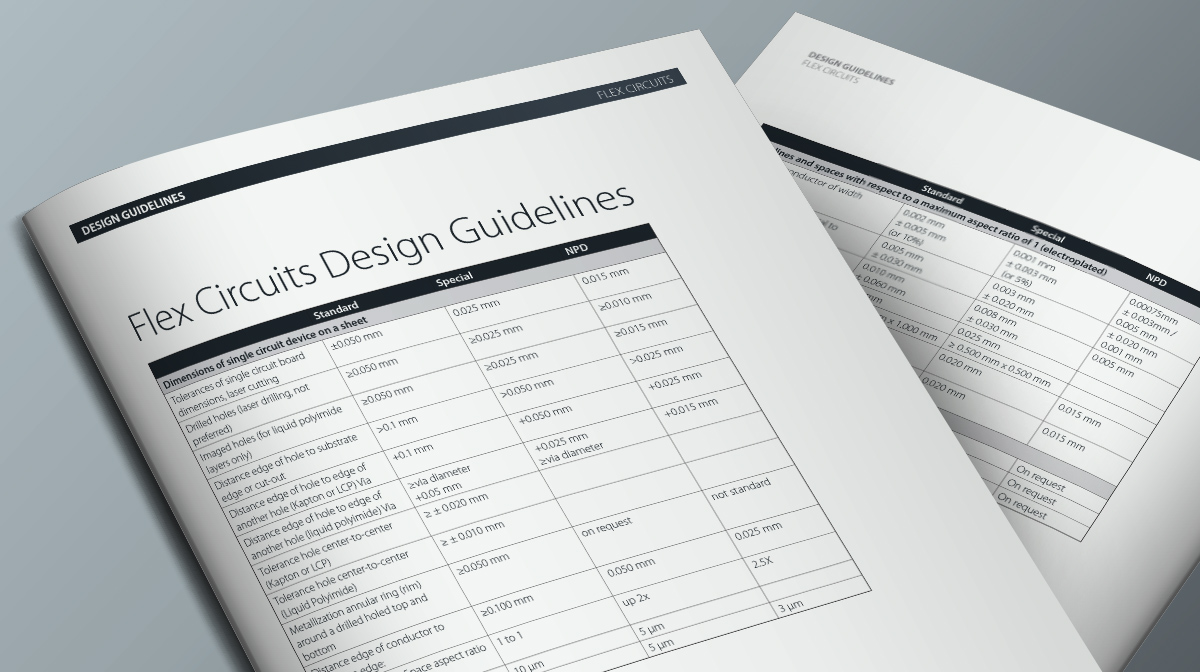

Flex circuit design rules. We would be pleased to help you in delivery panel design for rigid flex solutions. Heterogeneous system rigid circuit board wiring harness flex soldered in or plugged detachable. For flex annular rings need to be larger for flex rather than rigid. Flex and rigid flex boards.

Flex rigid design guide poster. Creative bending and flexing can save space and layers. Each supplier may have its own set of design rules and recommendations. Flex designs require button plating.

Designing flexible circuits is sponsored by all flex. See here the digital version or order here as paper version for free. Design rules for routing conductors on flexible circuits can be found in the ipc 2223 sectional design standard for flexible printed boards. Documents for manufacturing flex rigid circuit boards basically standards must be regarded such as ipc 2223 ipc 6013 the basic design guide from würth elektronik as well as variant specific design rules and our drying recommendations.

For designers of flexible circuit boards we recommend the ipc 2223 guideline design guidelines for flexible circuit boards which is available from the ipc online store or in german from the fed website. Flex circuits follow different rules for being optimal than rigid circuits. Understand that flex and rigid flex design rules are different. During testing you are trying to see how many cycles the flex circuit can withstand.

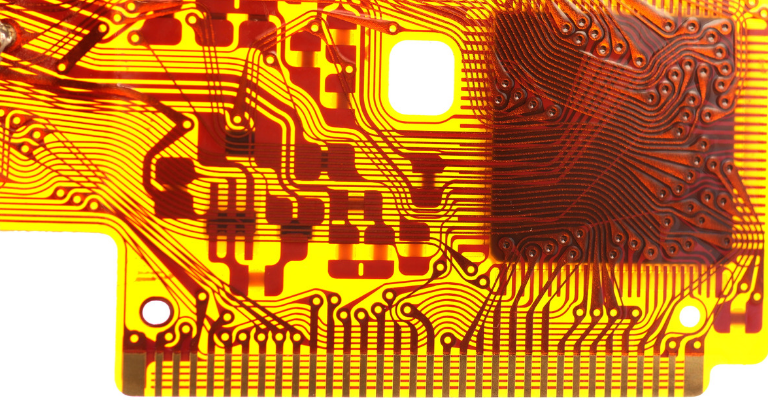

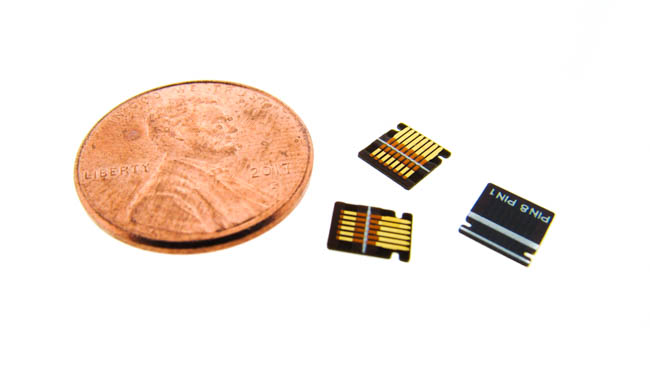

The most important design difference to keep in mind is the three dimensionality of a flex circuit. If you are not aware of this you will struggle with designing them. Applications which go beyond our standard design rules require technical clarification with our product management. Please keep in mind the following design rules for your flex or rigid flex circuit boards.

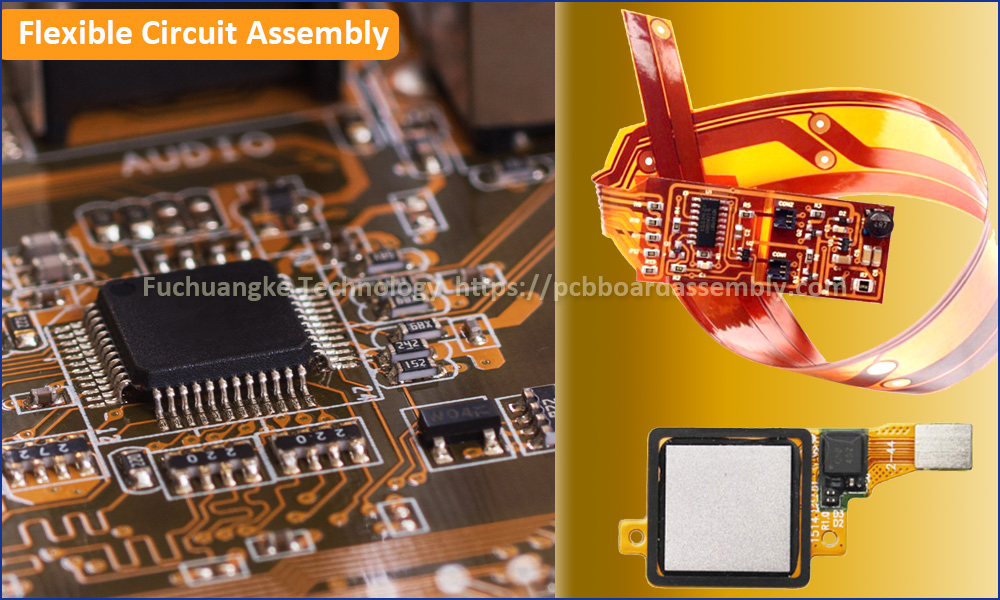

It may not be practical for all applications. The bend radius rule is just a general guideline. Below is a general rule on a flex circuit bend radius. However because flex circuit is unique it is a good idea to use the same material in prototype that will eventually be used in volume production.

Pcb design and layout will also be affected by your planned circuit density and line spacing. Figure 5 1 designing with a bias for copper improves the circuit s dimensional stability. Design differences flex circuit vs. You can also refer to the standard.

Also if you are using flex circuit design software that might not match up to the available guides for your flex circuits you will not have an easy time. Hardboards designing a flex circuit is only one step away from designing a hardboard. Using your circuit design software program position connector footprints in the proper locations and route conductors per schematic or net list.