Flexible Circuit Materials Companies

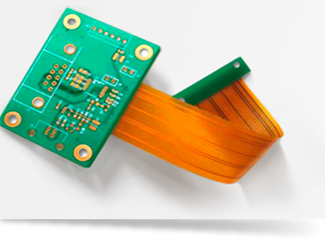

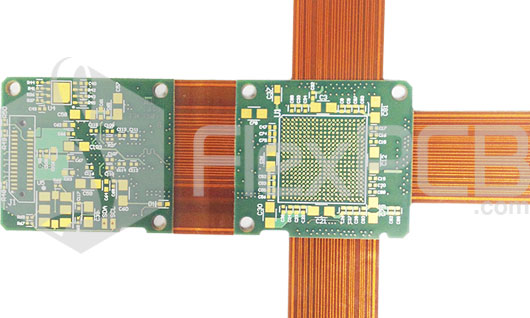

While most standard pcbs have a fiberglass or metal base flex circuit cores consist of a flexible polymer.

Flexible circuit materials companies. This blog post will provide a quick overview of common materials and constructions in flex and rigid flex pcbs. It s important to be aware of the materials used in flexible and rigid flex circuits. Tech etch uses this film as the base layer on single metal layer flex circuits and for inner layers of multilayer circuits. Enabling 5g networks and evs the laminate market is evolving to support the needs of high speed high frequency circuits that connect 5g networks and power the next generation of consumer electronics.

The majority of flex pcbs have a polyimide pi film as a substrate. Solutions in flex circuit stiffeners. The materials themselves are more expensive and they typically require more expensive machining operations. All flex is a flexible printed circuits manufacturer that has consistently delivered high quality flex circuits for two decades.

Insulator materials polyimide film is the most common insulator material used for flex circuits. Flexible circuits pose unique challenges for metallization. Typical single layer flex circuit stack up. The standard flexible circuit material uses 1 oz copper on this non polyimide proprietary molecularly flexible material for a total 3 mil thickness as flexible circuit substrate.

Flex circuit substrate materials fall into 2 general categories adhesiveless and adhesive based. Flat flexible circuits are able to fold into nearly any shape due to their flexibility and smaller size. These flexible circuit materials are available with 1 4 or 3 8 oz copper for super fine pitch flexible circuit applications of less than 1 mil line spacing and via. Even though you may generally allow the fabricator freedom to select the materials based on your application ignorance will not protect you from field failures of the final product.

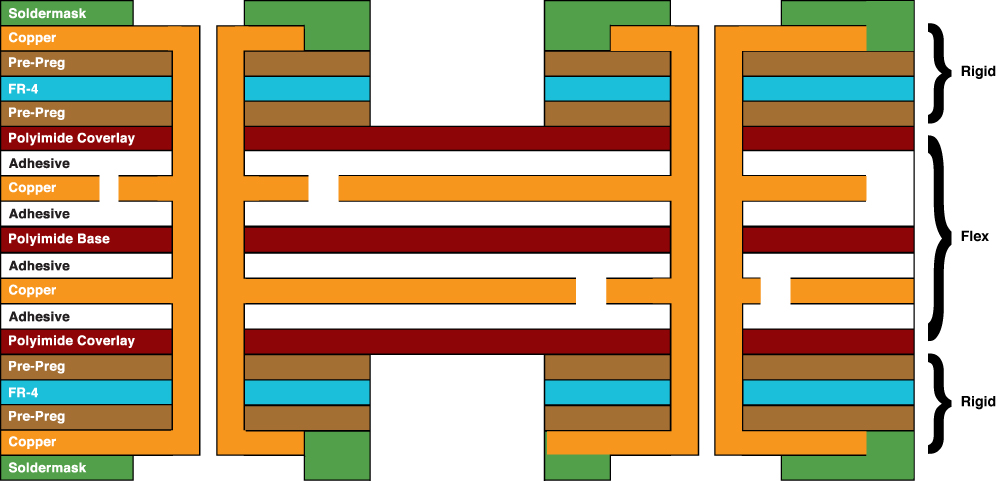

The designer needs to evaluate the flexible circuit design requirements to determine the best stiffener for the job. Copper can be an ideal material when deposited in a manner that is compatible with the flexible circuit manufacturing process which is often done on roll to. Fr 4 and prepreg combine to make up the insulating layers in the rigid portion of a rigid flex circuit. Adhesiveless adhesiveless materials manufactured as either cast dielectric on copper or sputtered copper on dielectric film.

We have responded to market demands and now offer heated circuits and deliver in high volume as well as prototypes from our two minnesota production facilities. Materials in flat flexible circuits include bare copper tin plated copper acrylic pressure sensitive adhesives polyester photoinduced electron transfer polyethylene naphthalate tin. Although they are small and light weight they are durable and capable of handling high density. Stiffeners in a flex pcb design add functionality to the finished part.

The tight bending radii present in many design configurations require flexible metal layers with high electrical conductivity.