Floating Roof Design Considerations

Forces from wind seismic effects snow and rain accumulation need to be accounted for.

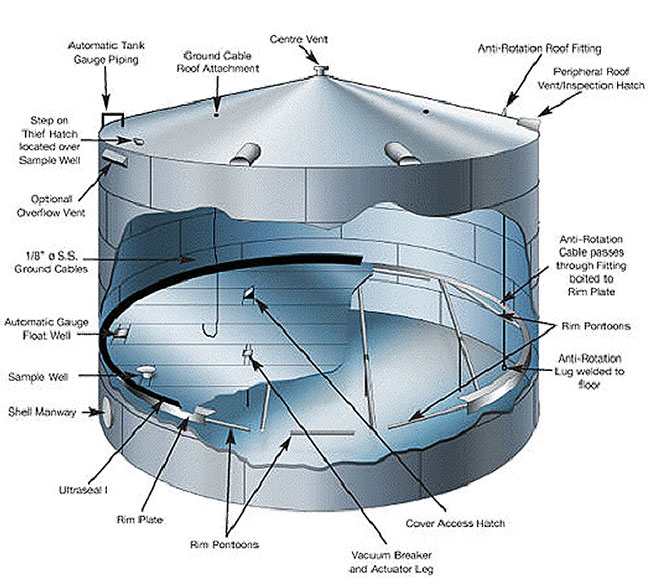

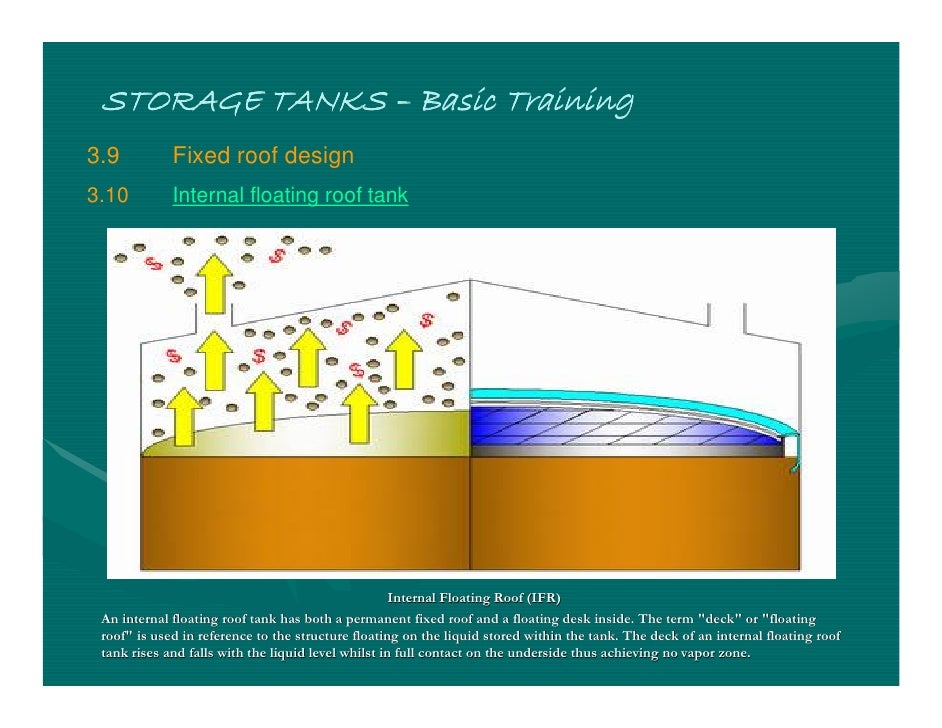

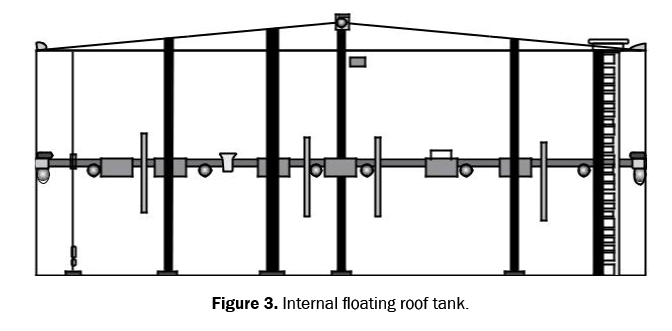

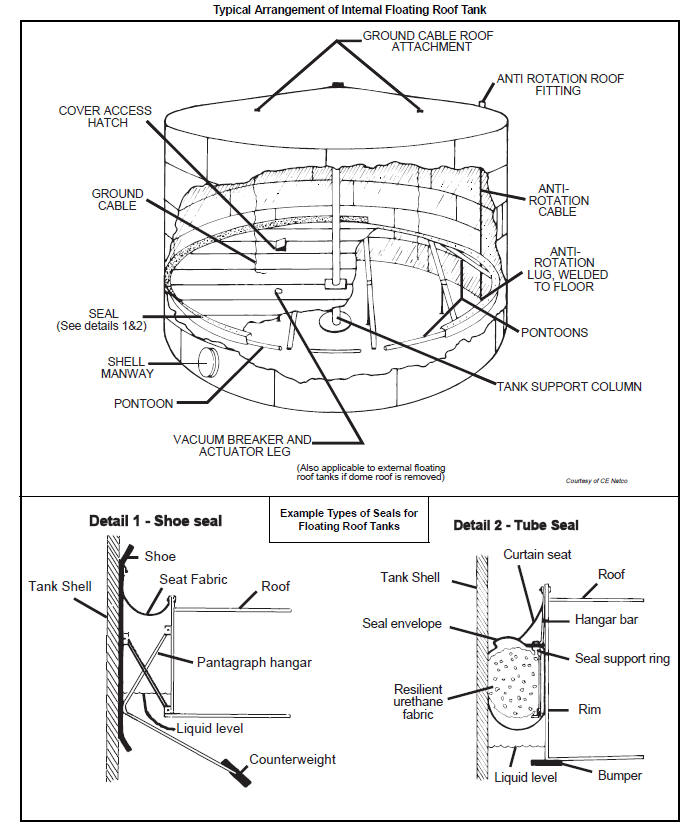

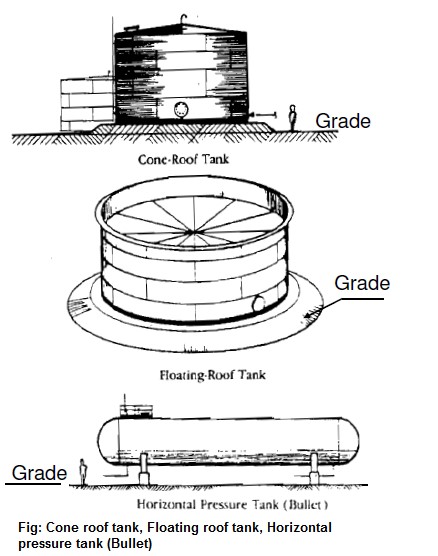

Floating roof design considerations. External floating roof tanks are generally made of steel and only has a floating roof as the top covering. The floating roof is made up of various elements such as fittings decks and rim sealing systems. Class a and or class b petroleum products same dyked enclosure. Group of floating roof tanks.

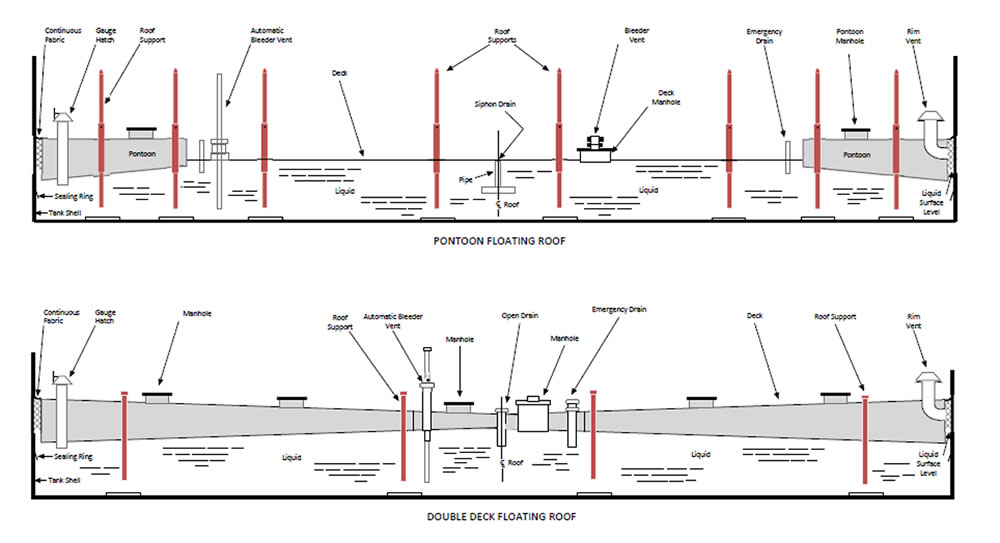

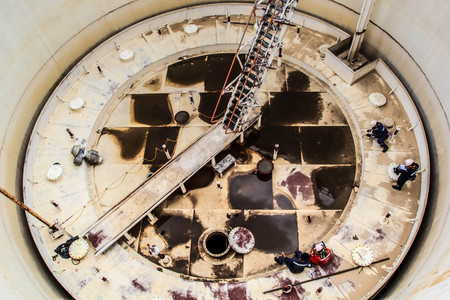

Large diameter floating roofs are efficient structures but require safe operating practices that are supported by effective inspection and maintenance programs. The choice between a single deck design and a double deck design requires an assessment of site wind loading conditions rainfall intensity and frequency and history of prior wind damage to floating roofs. The most common considerations for aluminum and steel floating roof purchases are low capital and maintenance costs long service life compatible service conditions product quality and. Normally set around 3 4.

Let s examine the five elements of floating roof design and how each will impact your application. Fixed cum floating roof tanks shall be treated as fixed roof tanks. Group of fixed roof tanks. This additional weight coupled with the.

Expect to lose about 7 8 total height from volume with ifr. Poor maintenance of floating roofs can have severe operational impact. The history of floating roof operations has been generally. Distance between levels is based on maximum fill rate x response time usually 5 minutes or 6 minimum bottom of tank minimum level depends on floating suction geometry to keep liquid from falling below roof for emissions.

In the shell design analysis shell stress design will be performed taking into consideration of all the considerably loading including hydrostatic pressure wind loading and seismic loading. An aluminum ifr is heavier around the perimeter due to the weight of the rim member and perimeter seal s. A tank storing the same product will have different loading considerations based on regional weather patterns at its location. The first consideration is chemical compatibility.

Following are some key considerations for selecting and designing floating roof seals above and beyond the existing standards that will help ensure asset longevity engineered safety and optimal working efficiencies. Design loading considers the environmental factors that will impact your roof. Factors that are related to the aifr rim space the annular space between the floating roof rim and the tank shell are extremely critical to the operation of the floating roof. Group containing both fixed roof tanks floating roof tanks shall be treated as fixed roof tanks.

How will mother nature impact your tank roof.