Floating Roof Tank Construction Procedure

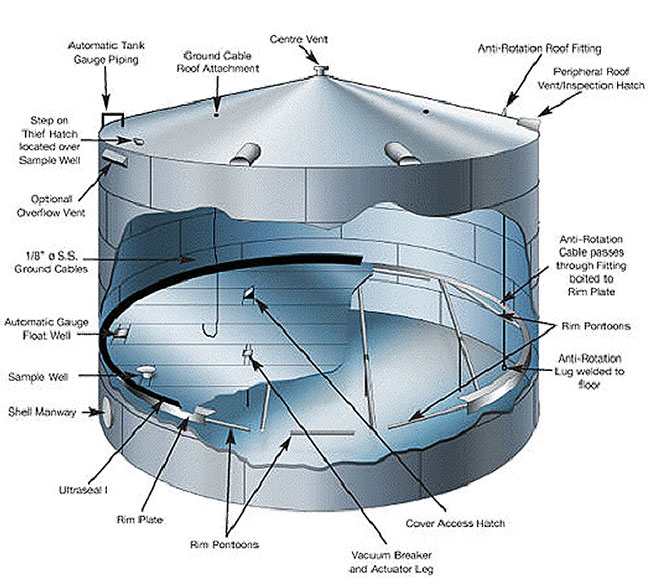

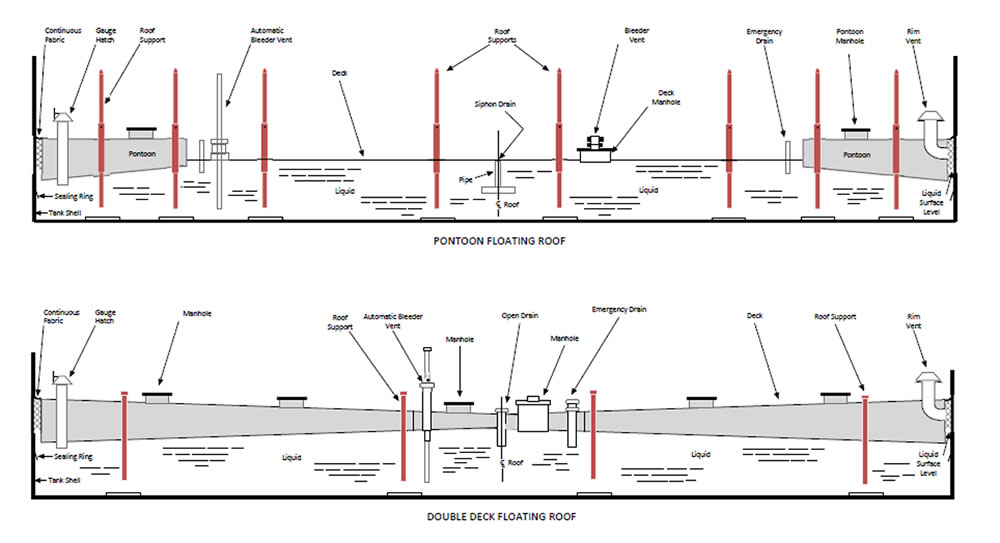

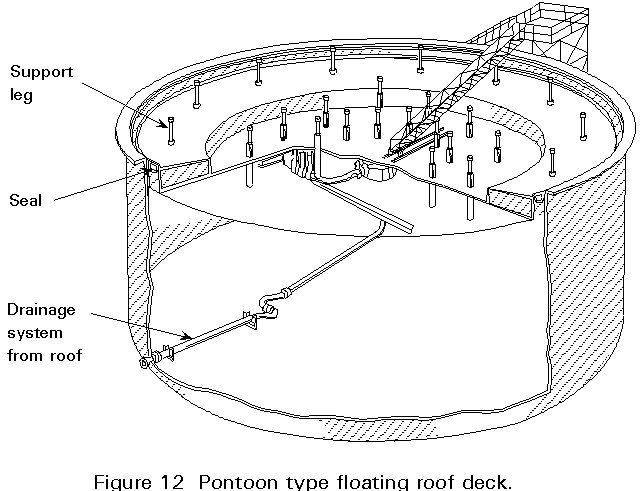

It consists of an open topped cylindrical steel shell equipped with a roof that floats on the surface of the stored liquid.

Floating roof tank construction procedure. Advantages of the traditional tank construction method. Flexible sealing system seals the gaps between the tank wall and the outer rim of the roof to protect the liquid from contamination and evaporation roof seal needs to be selected carefully as environment plays a great role in the building of a floating roof tank. Gas projects storage tanks system installation for lp propane aerosol odorless synthetic natural gases piping networks industrial building etc. Once this is done our crews can retrofit your tank with a new floating roof.

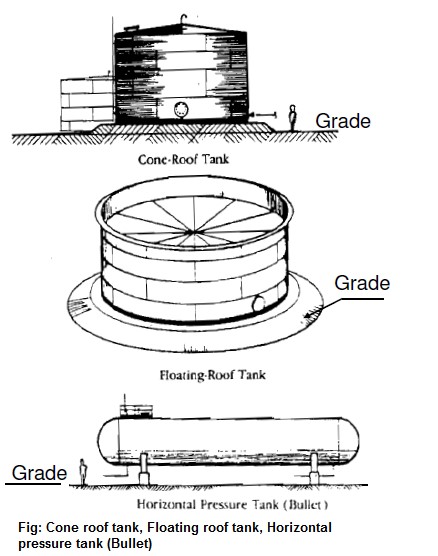

An external floating roof tank is a storage tank commonly used to store large quantities of petroleum products such as crude oil or condensate. Advance tank can evaluate the existing tank s design and determine what modifications need to be made to support a floating roof. Epc site construction projects tank farm plant piping storage tanks for crude oil finished products etc. We can take your cone roof tank and modify it to a floating roof for your changing work environment.

The traditional tank construction method procedure install the bottom of tank install the first ring the lowest of tank wall second ring of tank wall tank wall install the reinforcing ring install the floating roof install the accessories. Pressure vessels tanks manufacturing knock out drums filters vent drums separators etc. The floating roof tank animation describes the working principle in the training module. Various aspects of the floating roof tank working like the operation.

Concerns in designing construction and operation of a floating roof by taking an existing oil development project with it s readily available information as a base to design the tank and identify the problematic and lesson learnt throughout the project. This assembly method has the advantages of convenient erection fast progress production safety etc therefore it has been widely used all over the world. Prevent leaks into your secondary containment or to groundwater if you do not have a secondary containment system establish a baseline of tank condition and corrosion rates identify problems to perform repairs before you have a significant leak or release maintain your capital asset minimize chance of catastrophic tank failure. Floating roof tank has built in buoyancy that allows the roof to float on top of the content in open or closed top tank.