Floating Roof Tank Design Pressure

This increased pressure can be caused by inflow into the tank or increasing temperatures inside the vapor space.

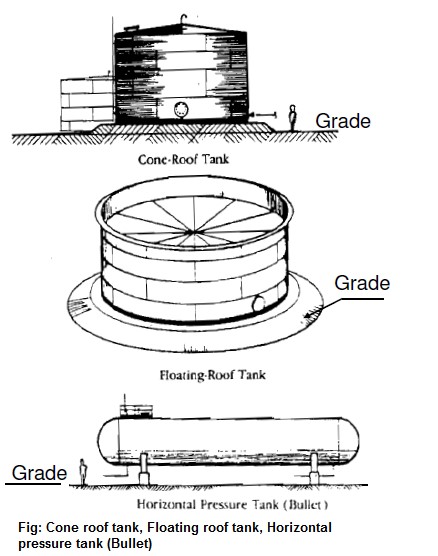

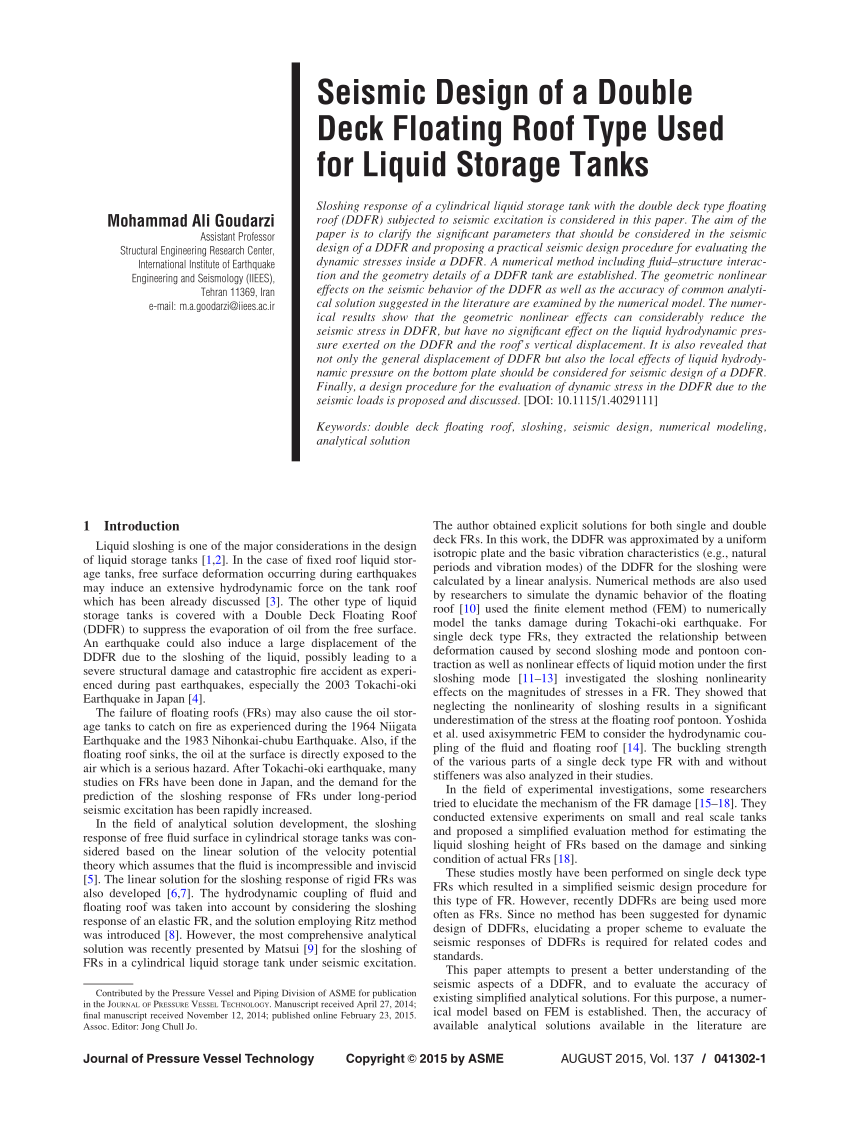

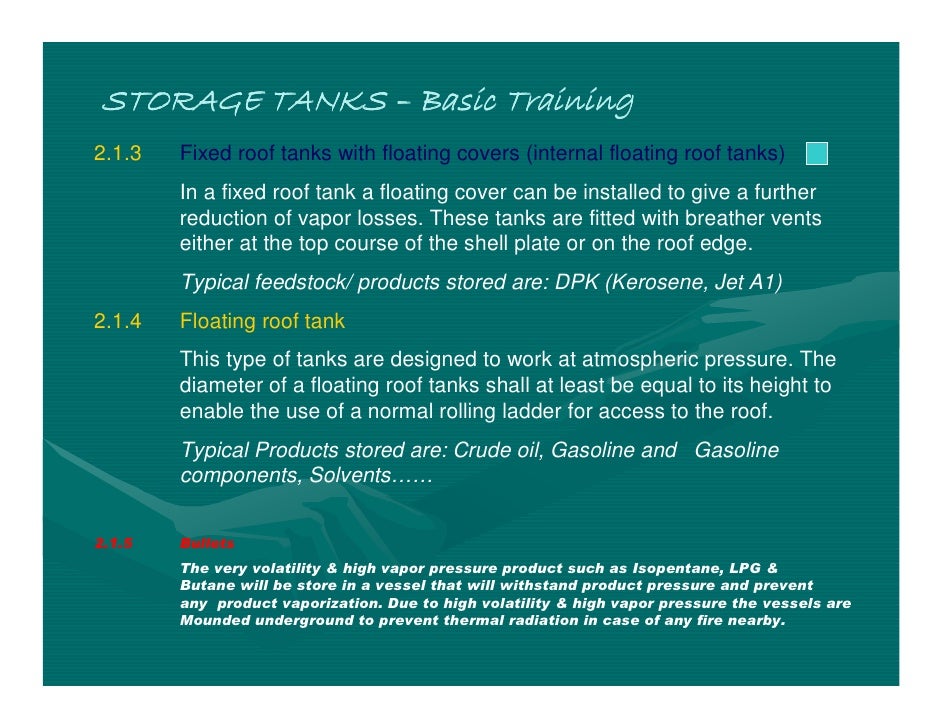

Floating roof tank design pressure. The roof rises and falls with the liquid level in the tank. 2 floating roof tank. Most current environmental regulations limit the product tvp to less than 11 1 psia. According to api 620 1 the maximum allowable pressure for storage tanks is 15 psi and if the pressure is larger than this value it is considered as a pressure vessel.

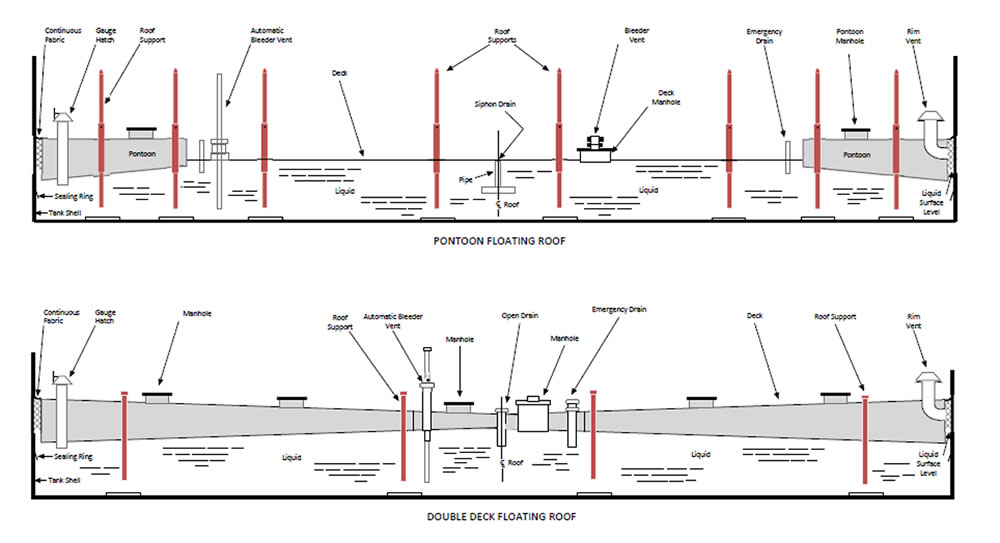

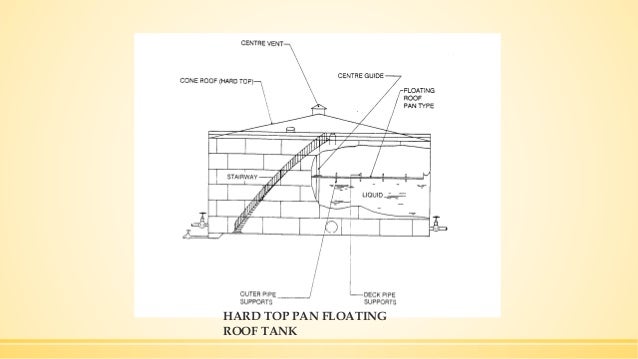

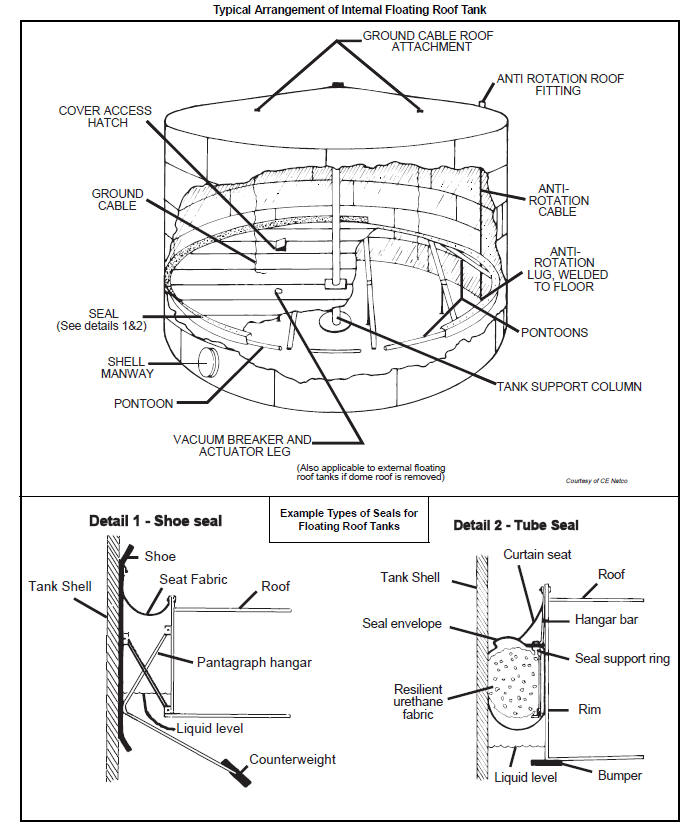

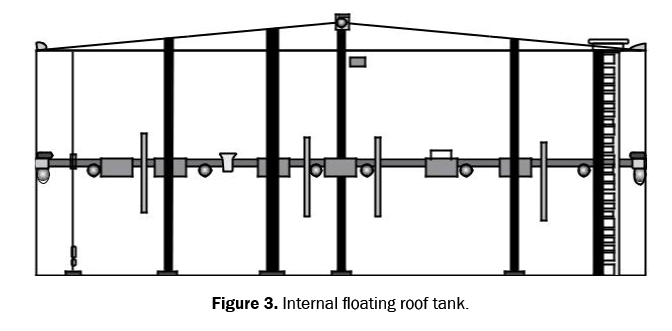

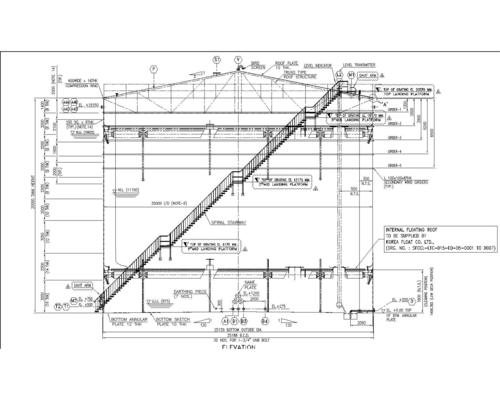

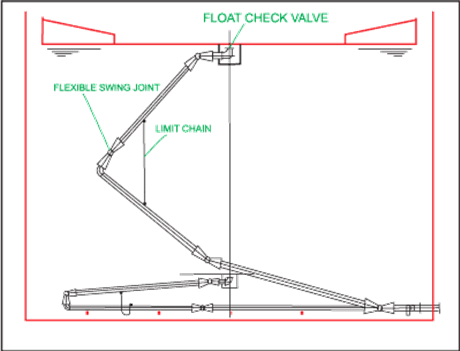

Implies the roof to float on liquid surface in the tank. As the tvp increases above 11 to 12 psia daily heating of the product under a center deck will produce enough vapors to balloon the deck. Common terms for tank pressure control are out breathing and in breathing. The storage tank design consists of two major designs that is 1 the shell design analysis and 2 the floating roof design.

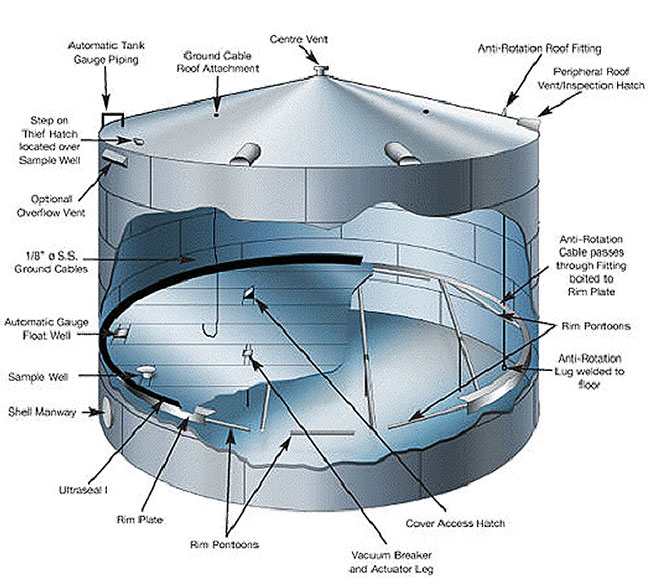

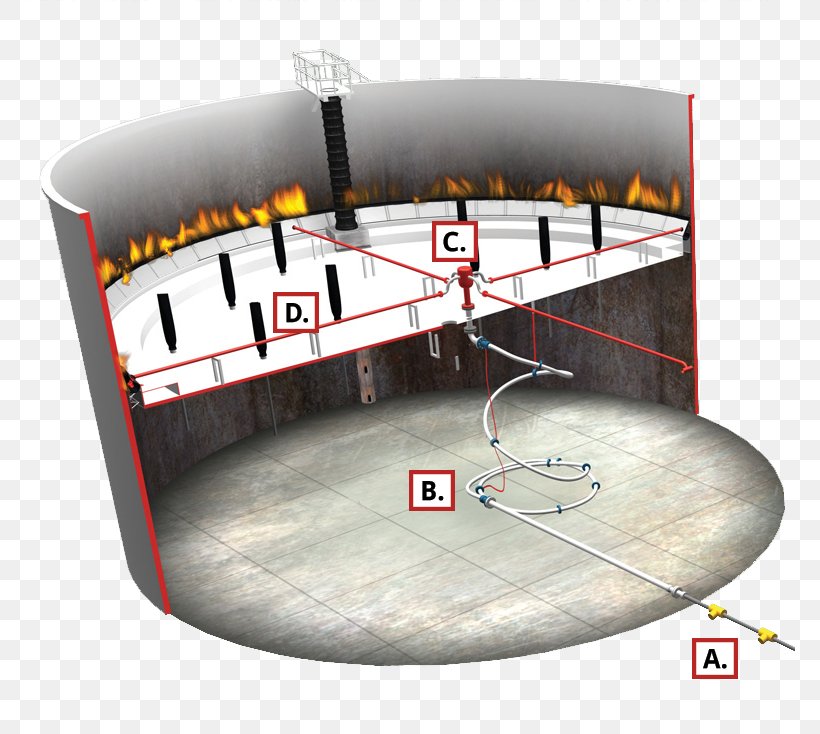

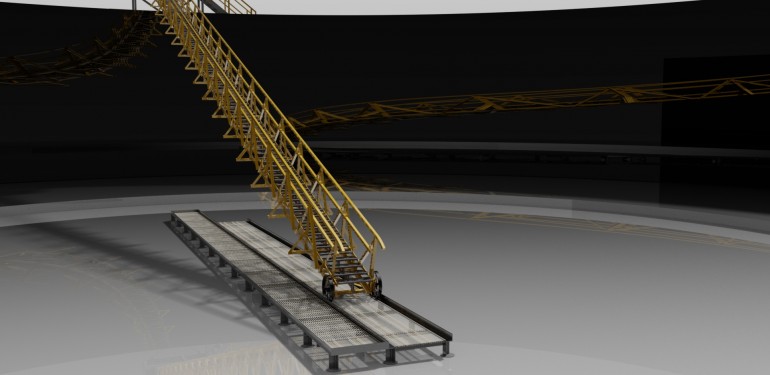

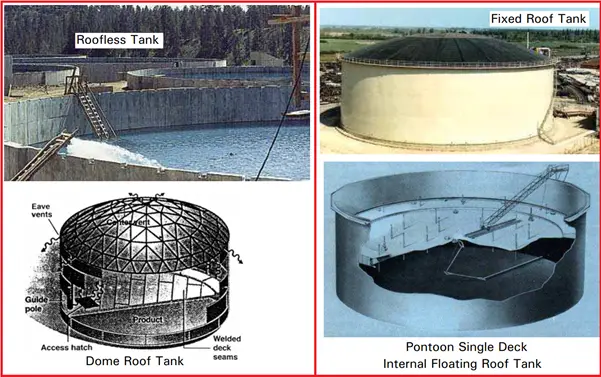

Atmospheric storage tank this type of tank operates from atmospheric pressure to 0 5 psi 0 034 bar. Product true vapor pressure tvp is the single most critical design parameter when selecting the type of floating roof. It consists of an open topped cylindrical steel shell equipped with a roof that floats on the surface of the stored liquid. In the shell design analysis shell stress design will be performed taking into consideration of all the considerably loading including hydrostatic pressure wind loading and seismic loading.

Closed floating roof tank this has an internal floating roof but eliminates natural ventilation of the tank vapor space. Out breathing is when a tank releases pressure. An external floating roof tank is a storage tank commonly used to store large quantities of petroleum products such as crude oil or condensate.

.JPG)