Foam Core Fiberglass Sheets

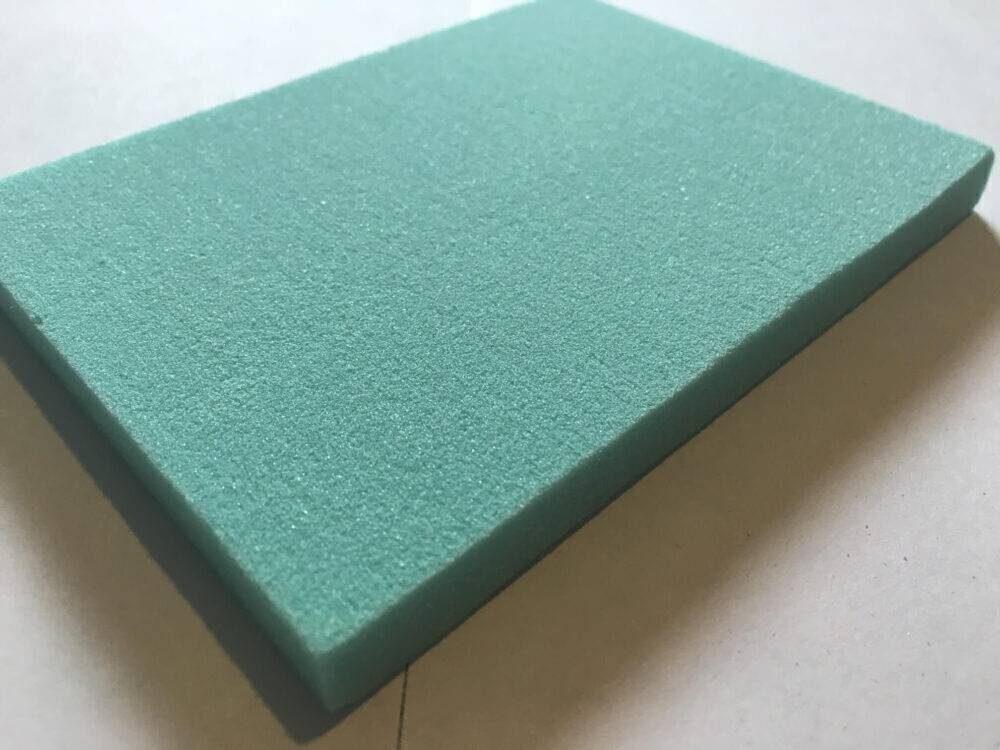

Divinycell h80 is a lightweight structural core for boats reefers doors containers when higher physicals than h45 are required.

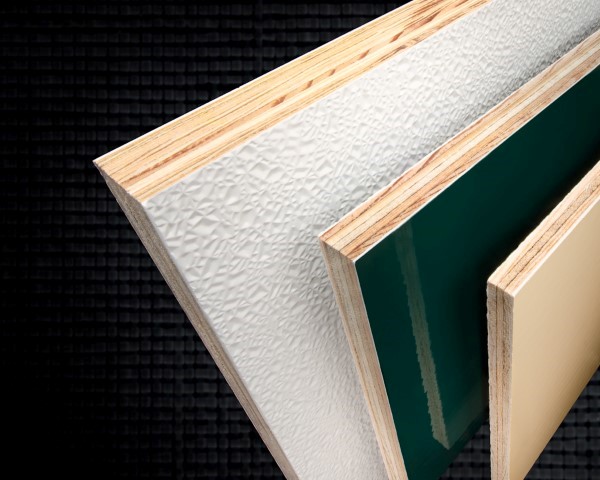

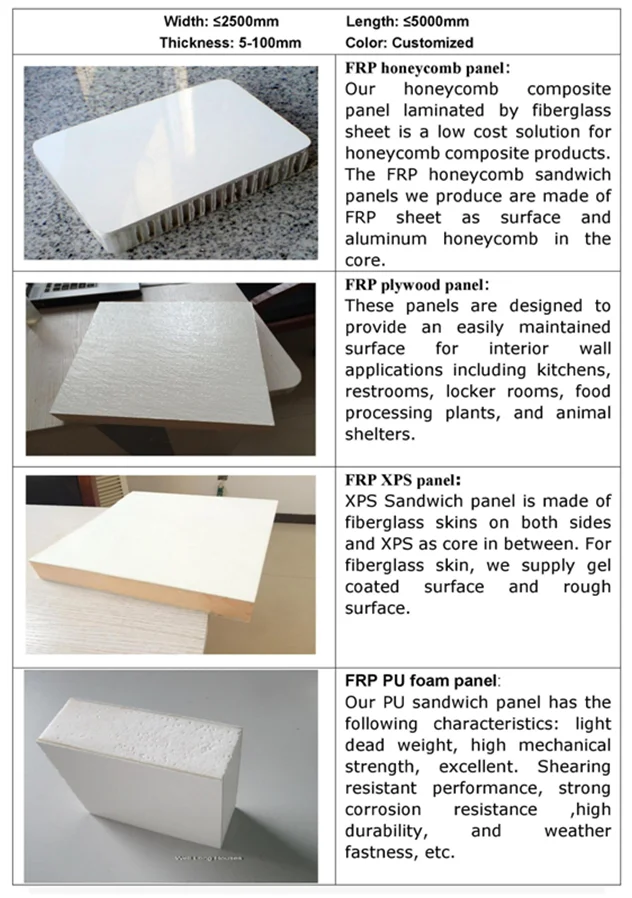

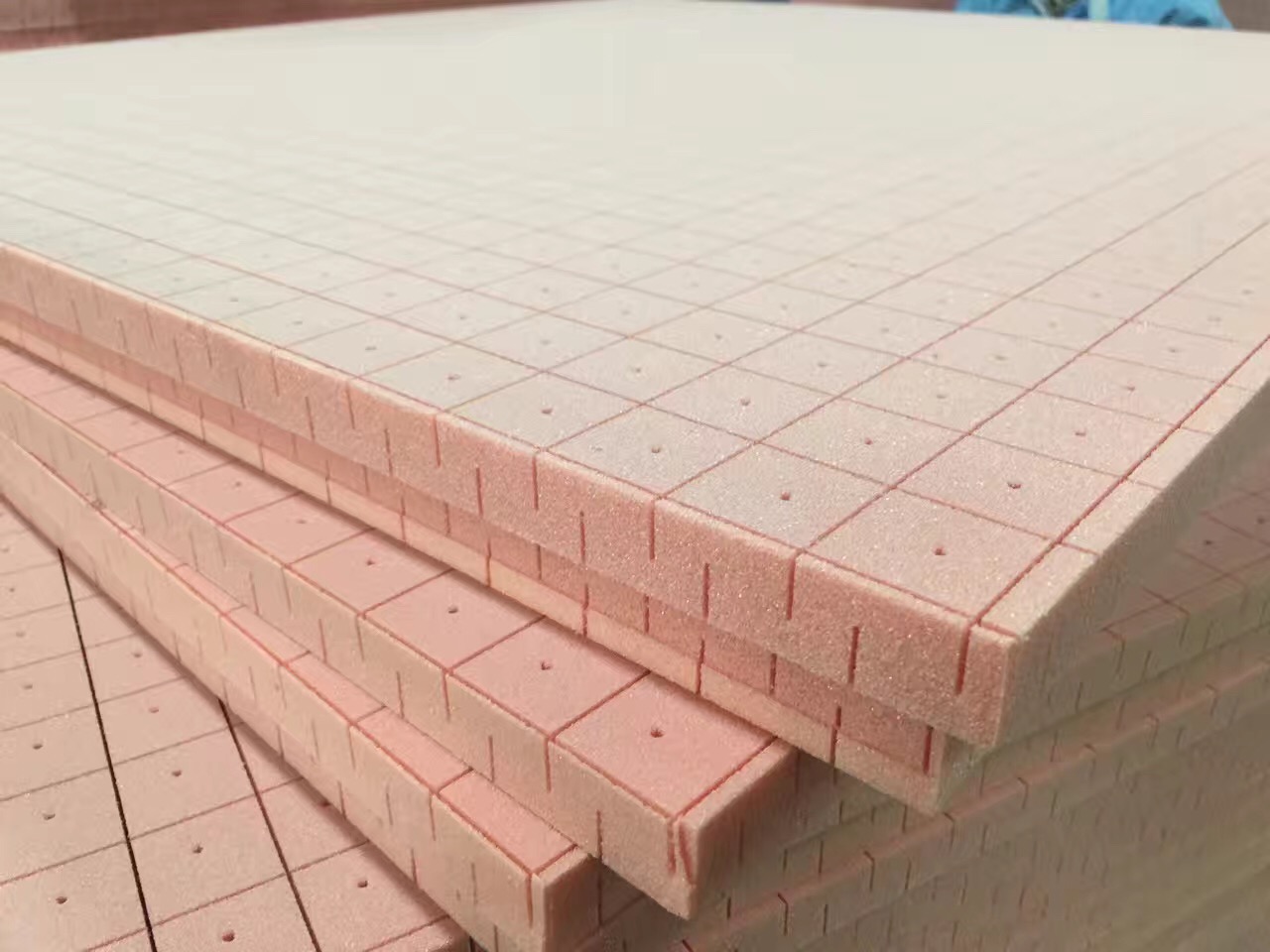

Foam core fiberglass sheets. Core materials are a great way to stiffen a composite structure without adding a lot of weight. Good ductility especially good for hull bottoms will contour to curved shapes. Plain divinycell sheets are not contourable and are excellent for decks and boat hulls. Cladfoam polyisocyanurate foam core structural panels consider fiber tech s structural insulated fiberglass panels when your project requires strength durability and superior exterior interior finishes in a one piece panel design.

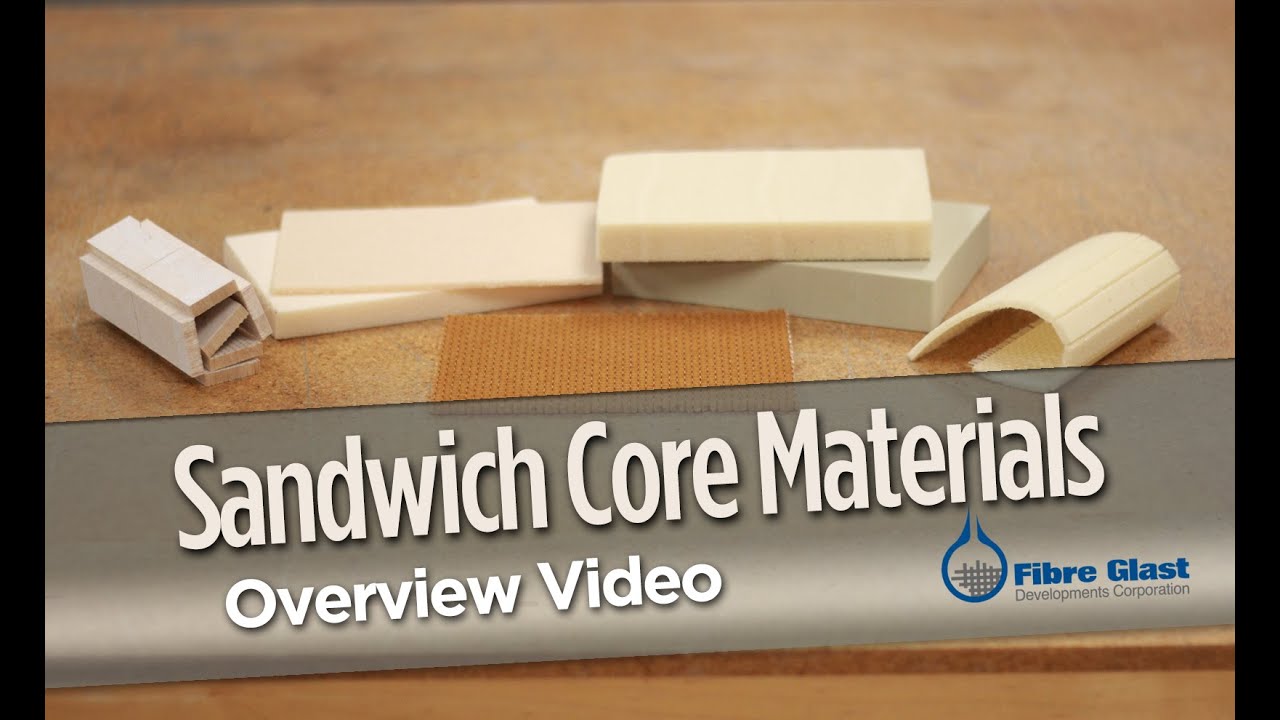

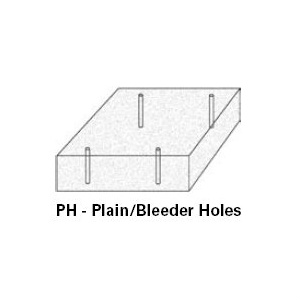

Sandwich panels are incredibly lightweight and strong. Scored sheets with scrim able to conform to curved surfaces. 21 abrasives 25 brushes rollers pans 19 boat parts and accessories 18 caulking 1 clothing 54 detailing 47 epoxy resin and glue 35 fiberglass 8 foam core material 16 gel coat 3 hardware 3 hardeners 23 mold fabrication 51 paint 8 polyester resins 25 putty fillers 22 safety 9 solvents 13 measuring mixing 9 tape 2 trims and seals 26 tools 3 vinyl. We stock divinycell pvc foam balsa core coremat and marine grade plywoods for use in composite construction.

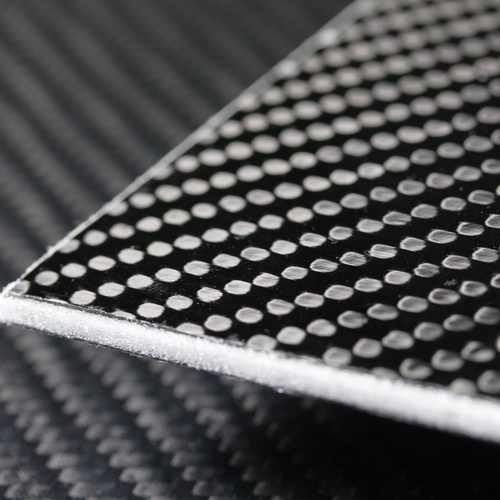

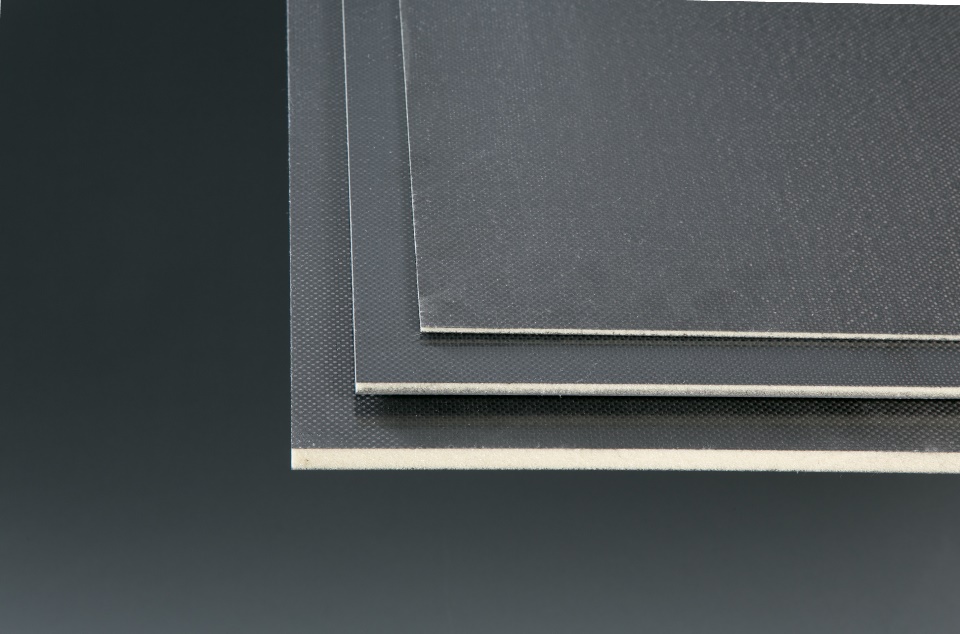

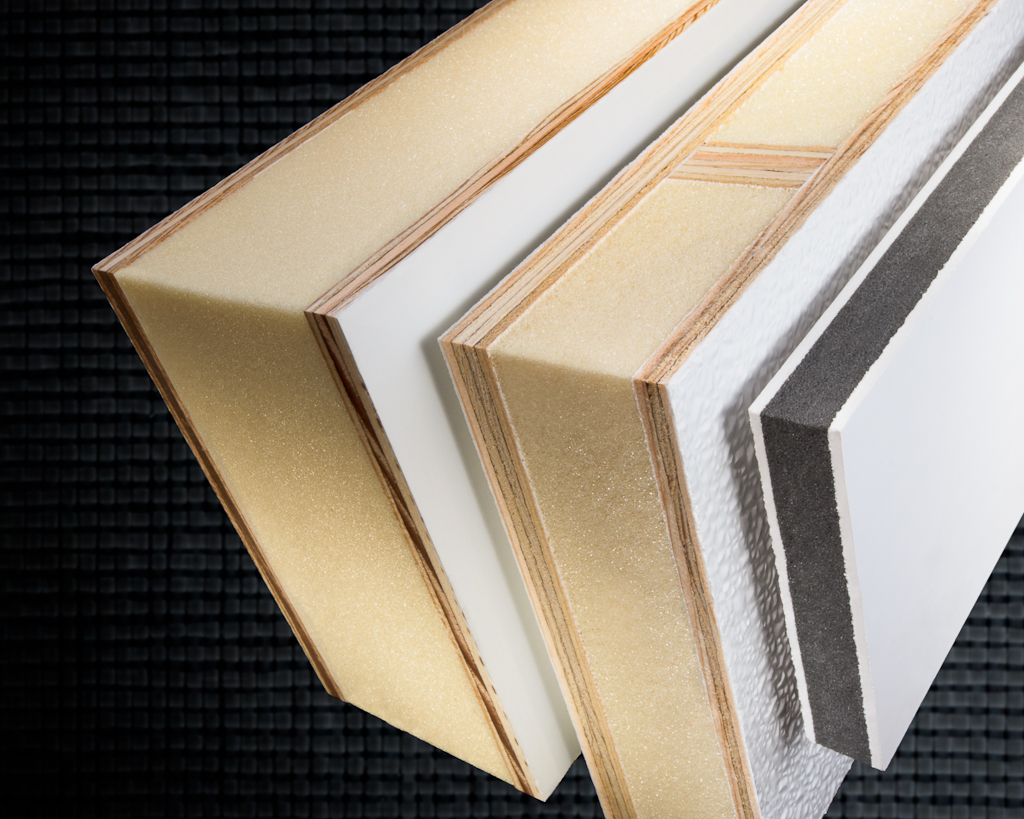

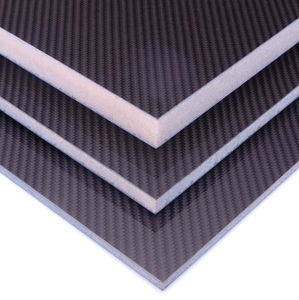

Product is sold by the individual 4 x 8 sheet. Excellent for hull and deck core replacement and anywhere that a robust non wood core is desired. Great for hulls and decks. Foam core sandwich panels foam bonded to twill carbon fiber lightweight high stiffness great for aerospace and automotive applications when weight savings are critical strength is a requirement and quick delivery a must these foam core sandwich panels offer huge advantages over solid composite plates.

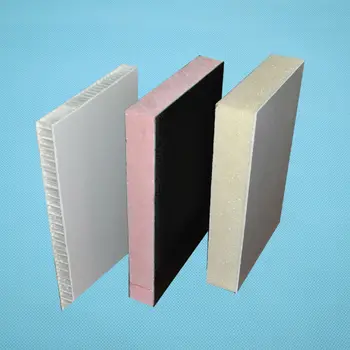

This sheet foam is a rigid closed cell material with excellent thermal insulation and flotation properties. Our sandwich panels are cured with high temperature and under pressure resulting in fully consolidated fiberglass skins that are completely bonded to the foam core. A sandwich panel is a composite panel that uses stiff and strong skins face sheets bonded to a lightweight core. It is the true structural sandwich panel.

Common core materials are foam and aluminum or aramid honeycomb. Mix and pour polyurethane foam. It is compatible with both polyester and epoxy resin systems. Common skin materials are carbon fiber and fiberglass.

.jpg)