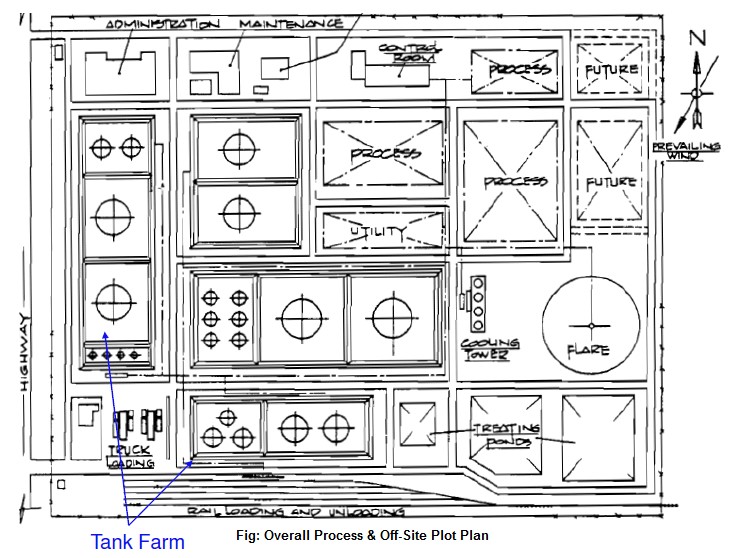

Floating Roof Tank Design Procedure

Design of a floating roof crude oil storage tank of 100 000bpd capacities proceedings of the 44 th nsche annual conference owerri 2014.

Floating roof tank design procedure. Jimmy dorcas etim 2014. In this study three cases were applied to analyze the buoyancy of the floating roof in each case. Floating roof tank has built in buoyancy that allows the roof to float on top of the content in open or closed top tank. The obeyed methodology of this study is by calculating the center of gravity and moment of inertia of the floating roof in each case.

To study roof pontoons design a buoyancy analysis of the floating roof was established with punctured pontoons. In the shell design analysis shell stress design will be performed taking into consideration of all the considerably loading including hydrostatic pressure wind loading and seismic loading. However these requirements must be treated as minimum requirements and may not be adequate to satisfy tank operating loads under specific site conditions. Floating roof tanks are commonly protected against lightning ignition by bonding the floating roof to the seal shoes at no less than 3m 10ft intervals use of insulating sections in the hanging linkages covering sharp points on hangers with insulating materials and installation of electrical bond straps across each pinned hanger joint.

Advantages of floating roof tank.